To thrive in the industry 4.0 era, many factories are always looking for ways to improve efficiency and enhance reliability, and power plants are no exception. Any idle time resulting from an operational glitch directly impacts both the top and bottom lines of the business. Thus, the network is central to everything the plant generates. To improve the network infrastructure, the Milesight CPE units, which are 5G-ready and Wi-Fi integrated, are implemented in a power plant to provide a wireless solution for high-speed, reliable connections with low latency.

Project

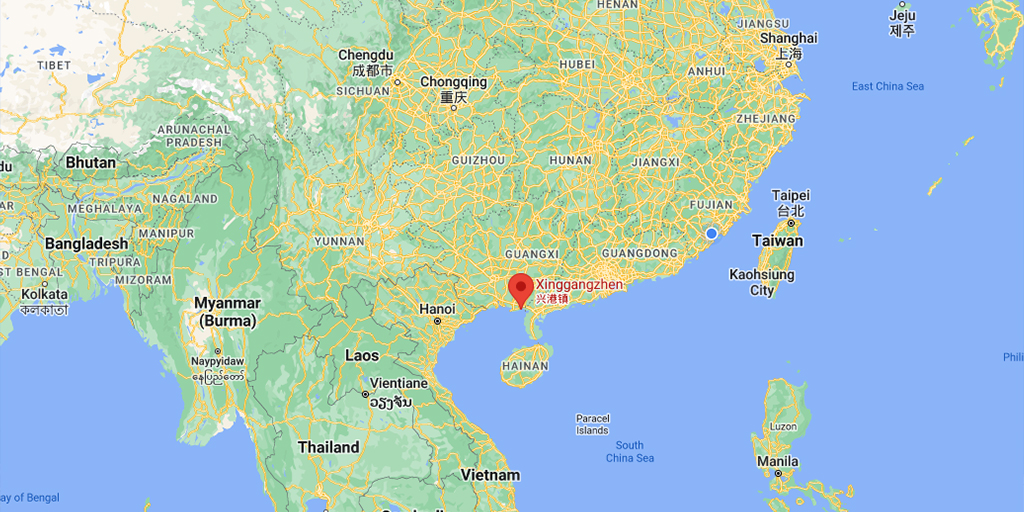

The Beihai Power Plant Phase II is an expansion project, which is a major project promoted by GFIG to build a stable and reliable “energy network” for Guangxi province, China.

A 24-by-7 operation spread across 136,500 square meters (0.05 square miles). They were actively seeking a solution with the latest wireless network technology so that they could successfully interlink all mobile devices and office equipment without any downtime, meanwhile, exchange the data securely on the private network.

Challenges & Requirements

Frustrated with network downtime, unstable connectivity, and spotty coverage, this coal-fired Beihai power plant was desperate.

- Wireless Deployment

Time equals money. Wired deployment is not an option due to the tricky and time-consuming process, and if a buried cable is broken, it is expensive to repair, while industrial wireless deployment saves significant costs compared to an equivalent wired installation.

- Extensive Connections

Many smartphones and tablets in areas of the plant must be connected to wireless networks to enhance workers’ capabilities, saving time and money in the long run.

- Dedicated Network

A dedicated or private network is preferred as it is self-contained that can be deployed almost anywhere and managed centrally, providing a higher level of security.

- Harsh Work Environment

Metal buildings, machinery, massive magnets, extremely hot temperatures, and high humidity made it difficult to gain dependable signals or stable connections.

Having tried some of the most well-known Wi-Fi and cellular solutions on the market, the IT network staff at the power plant turned to Milesight 5G CPE units with minimal investment in the new infrastructure.

Related Products

Milesight industrial-grade CPE device with 5G cellular and Wi-Fi convergence that has been designed to ensure reliable, continuous, high-speed data communications in extreme operational environments, supporting heavy-duty applications.

Solution

The company had been using Wi-Fi AP with signal band 2.4GHz to connect various instrumentation and industrial tablets to collect data and send instructions to workers. While useful for office connectivity, in such a challenging environment, that out-of-date Wi-Fi network could not keep up with the coverage requirements and was not able to deliver the reliability required to support the critical communications essential to the manufacturing process. Now, instead of using Wi-Fi APs, they use UF51 5G CPE. They can cover indoor and outdoor areas with the same technology and have no additional hassle. The built-in Wi-Fi of UF51 CPE has a 2 by 2 MIMO dual-band IEEE 802.11b/g/n/ac (2.4GHz & 5GHz) with speeds of up to about 1.7Gbps, which ensured a seamless connection for max. 128 endpoints.

The big benefit is not only the capacity upgrades but also considerable in the area of managing. One day is enough to settle down the settings of a hundred CPE units and build up a smooth cooperation between the factory and mobile network provider. Setting up a network is fast as Milesight UF51 CPEs can be managed over the air. For example, software updates can be carried out without physical access, so these 5G CPE units can be safely managed and controlled using the DeviceHub management platform. This is more than welcomed news to the IT staff.

The plant has a need to keep data on its premises and cover the plant indoors and outdoors. 5G makes it possible. SIMs are core components that enable reliable mobile connectivity, the dedicated 5G SIM cards from a local mobile network operator are inserted to optimize the network and guarantee a high level of security. Thanks to the 4 by 4 built-in OMNI directional antennas Milesight CPE can pick up the sub-6Ghz band signals wherever it is placed.

Rich interface design is another reason UF51 CPE was selected for this application. Considering the industrial operations in the future, the serial ports (RS232/RS485) can be used to read data from machine components, which can be evaluated directly on the edge. And the digital input and output interface is ideal for switching on or off stuff remotely. A GNSS receiver provides an exact device position.

Now more than 80 units of UF51 CPE are up and running to connect the digital devices in the power plant, transmitting critical data reliably from the vast rural areas and bringing the following benefits to the end user:

Benefits

- Rapid Deployment

Minimize expenses with wireless technology designed to deliver optimized deployment costs.

- Increased AP Capacity

High-end specification, increased Wi-Fi capacity, and best data security.

- Minimal Investment

UF51 CPE is a multi-function device, which saved investment on purchasing multiple Wi-Fi APs, cellular gateways, or routers.

- Industrial-grade Performance

Milesight UF51 CPE is designed for wide temperature ranges from -40°C to +70°C with IP67 protection against humidity and dust under harsh conditions.

Successful 5G and Wi-Fi Network Convergence Solution for a Power Plant in China with Milesight CPE